Spearhead process

The Spearhead Process is a systemized, adaptable approach for solving unique project complexities. It is an unconventional process for unconventional structures.

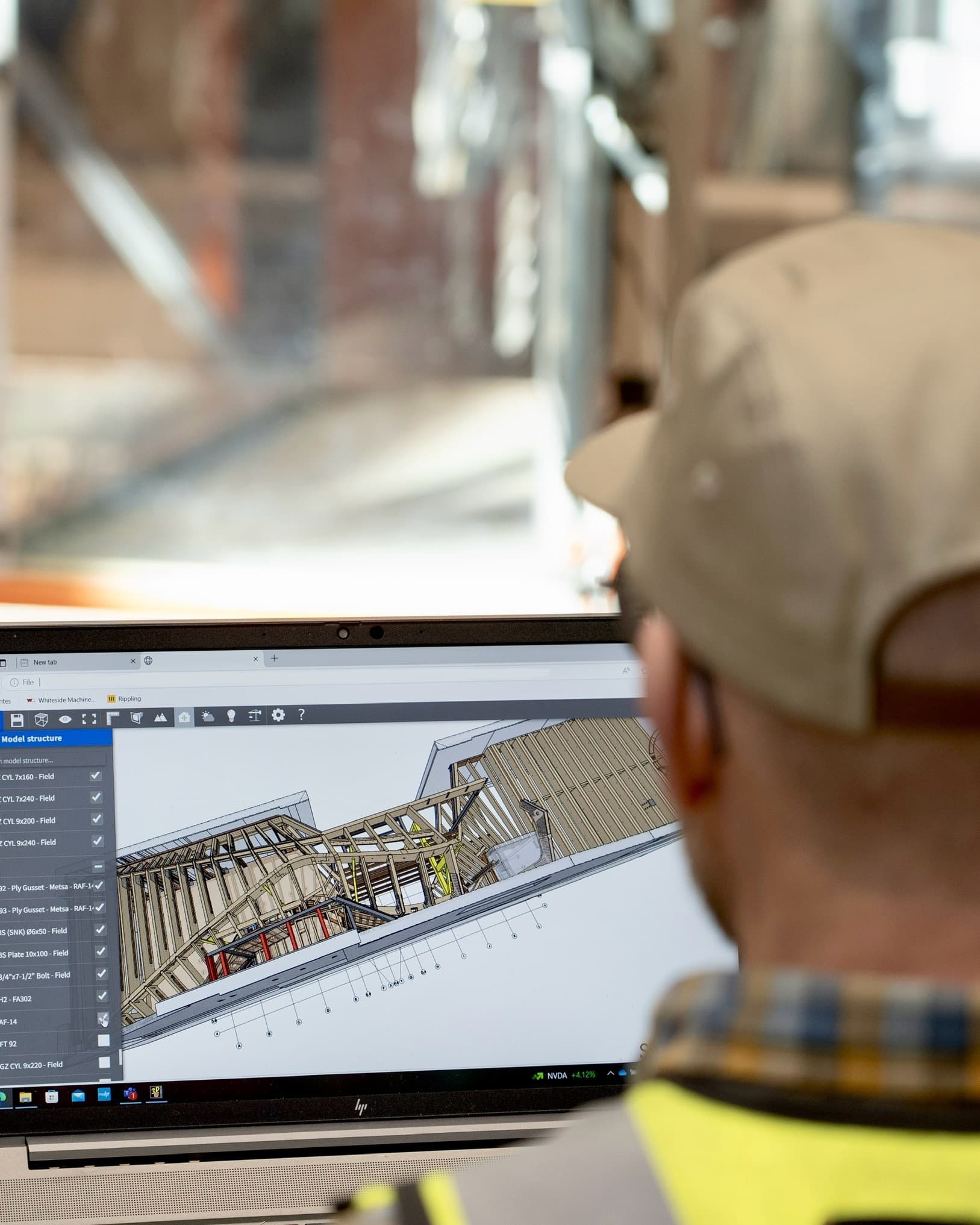

Involve us early in a project. We work intimately with architects, builders, and engineers on a centralized fabrication model.

Uphold design integrity

We establish a digitally coordinated feedback loop between design, fabrication and build. This reduces scope divisions, increases collaboration and introduces project efficiencies while reinforcing an architect's intent.